Repair Air Conditioning Unit: Professional Cooling System Restoration Guarantees Your Home Stays Comfy During The Most Popular Days

Common Cooling Issues

Have you ever felt that unexpected rush of warm air simply when you expected a cool breeze? It's discouraging, isn't it? Numerous house owners face this predicament, frequently unaware of what hides underneath the surface area of their air conditioning system. Let's unwind the mystery behind some of the most regular concerns that require prompt a/c repair.

Why Will Not My Air Conditioning Cool Effectively?

When your air conditioner system blows lukewarm air instead of a refreshing chill, it's a clear indication something's off. A stopped up filter or low refrigerant levels often play the bad guy here. Envision trying to breathe through a headscarf on a hot day-- that's what a dirty filter does to your system. Ever wondered why your energy expenses spike when the cooling drops? That's your air conditioner having a hard time more difficult to compensate for ineffectiveness.

Weird Sounds and What They Mean

Clicking, buzzing, or rattling noises aren't just noises-- they're cries for aid. A loose belt or a stopping working motor might be the culprits. One house owner stated how a relentless grinding sound ended up being a damaged compressor, saving them from a complete breakdown by acting quickly.

Typical Problems at a Glance

| Symptom | Likely Cause | Quick Repair |

|---|---|---|

| Warm Air | Low refrigerant or dirty filter | Replace filter, check refrigerant levels |

| Water Leakages | Blocked drain line or frozen coils | Clear drain line, thaw coils |

| Uncommon Sounds | Loose parts or motor issues | Tighten up parts, check motor |

Is Your air conditioner Biking On and Off?

Short cycling is more than an inconvenience; it can drastically minimize your system's life expectancy. This might signal an oversized unit or a thermostat problem. Have you observed your unit turning on and off like a flickering light? Don't ignore it. It's a subtle tip prompting you to hire the experts before it develops into a costly disaster.

- Dirty filters and coils trigger airflow problems.

- Thermostat breakdowns result in irregular temperatures.

- Electrical problems can stop your air conditioner from beginning.

Essential Tools for Cooling Repair Work

Ever stood in front of a sprawling a/c unit wondering which tool will unlock the secret? The right instruments can make all the distinction between a quick fix and an endless afternoon of disappointment. A digital manifold gauge set isn't just an expensive gadget; it's the detective's magnifying glass in the world of refrigerant pressure. Its accuracy assists identify leakages or imbalances that a casual glimpse may miss out on.

When handling stubborn or rusted parts, a quality tubing cutter is worth its weight in gold. It slices through copper pipes easily, preventing damage that could cause expensive leaks. Have you ever tried to bend copper tubing by hand only to end up with kinks? Avoiding this needs specialized bending tools created to maintain the pipeline's integrity.

Tools That Experts Swear By

- Air pump: Vital for eliminating wetness and air from the system before recharging refrigerant, making sure optimal efficiency.

- Leak detector: A must-have for capturing unnoticeable refrigerant leakages that can cause system inadequacy.

- Multimeter: Beyond measuring voltage, it's essential for detecting electrical faults within the a/c's control system.

- Fin comb: A small yet magnificent tool that corrects bent condenser fins, improving air flow and efficiency.

Pro Tips for Utilizing Air Conditioning Repair Tools

- Constantly confirm your gauge readings against manufacturer specifications; even experienced techs verify to prevent pricey misdiagnoses.

- When utilizing a vacuum pump, make sure all valves and pipes are airtight; a minor leakage can destroy the evacuation process.

- Tidy your fin comb regularly. Dust and grime can cause it to snag, destructive delicate fins even more.

In the heat of summertime, a malfunctioning compressor or clogged filter can feel like a ticking time bomb. Equipped with the right tools and knowledge, the repair becomes less of an experience and more of a gratifying puzzle fixed. Isn't it click here curious how a well-calibrated gauge or a basic leakage detector can change the entire outcome?

Step-by-Step Repair Work Process

Ever discovered how your a/c system starts to sputter, barely whispering the cool breeze it once delivered? The very first relocation is an extensive diagnosis-- since guessing only wastes time and resources. You might start by examining the thermostat settings, however sometimes the genuine perpetrator prowls deeper.

1. Initial Inspection and Diagnostic

Begin by powering off the system to prevent shocks. Open the access panels and aesthetically check for charred wires, stopped up filters, or ice buildup. A common oversight is disregarding the condenser coils; dust and dirt here can choke effectiveness. Use a multimeter to test electrical elements and verify if the compressor is getting power.

2. Identifying Refrigerant Issues

Does the unit blow warm air? That's often a sign of low refrigerant levels or leakages. Specialists utilize a manifold gauge set to determine pressure precisely. Keep in mind, overcharging or undercharging the system can cause irreparable damage-- precise measurement is essential.

3. Cleaning Up and Element Replacement

Often, a simple coil cleaning restores the system. Other times, it requires swapping out capacitors, contactors, or fan motors. Replacing these parts involves mindful disassembly and reassembly; skipping actions can lead to further breakdowns.

4. System Testing and Calibration

When repair work are made, switch the system back on and observe its behavior. Procedure the temperature drop across the evaporator coil-- it needs to be roughly 15-20 ° F. If not, recalibrate the thermostat or look for airflow obstructions.

Specialist Tips

Air Conditioning Companies Near Me [:location]Air Conditioning Company [:location]

Air Conditioning Service & Repair [:location]

Air Conditioning Repair [:location]

Air Conditioning Repair Service [:location]

- Avoid running the compressor without refrigerant-- this stress out the motor quickly.

- Use a UV color to locate elusive leaks; they're frequently concealed in hard-to-reach locations.

- Never neglect the drain line-- blockages here can cause water damage and system failure.

- Wear insulated gloves when managing capacitors; they keep charge and can provide a nasty shock.

Defending Against Unexpected Breakdowns

Have you ever questioned why your air conditioning unit sputters to a stop right at the peak of summertime? The reality is, disregarding regular upkeep frequently invites unexpected failures. Dust, particles, and damaged elements wage a silent war inside your unit. Preventive upkeep is the ace in the hole-- capturing minor concerns before they spiral out of control.

Expert Tips for Keeping Your Air Conditioner in Top Forming

- Tidy or change filters month-to-month: A clogged filter chokes air flow, requiring the system to work overtime and speeding up wear.

- Check coil fins: Bent fins limit air passage, similar to a traffic congestion in your cooling system. Utilize a fin comb to straighten them thoroughly.

- Examine refrigerant levels: Low refrigerant can trigger the compressor to get too hot, a precursor to costly repair work.

- Clear the condensate drain: Obstructions here can lead to water damage and mold development, a surprise perpetrator behind lingering odors.

- Take a look at electrical connections: Loose electrical wiring or rusty terminals frequently trigger intermittent failures, a subtle caution indication.

When Was the Last Time You Listened to Your air conditioner?

That faint rattling or uncommon hum might appear unimportant, however it's a precursor to larger mechanical problems. One summer, a customer pointed out a soft buzzing sound. A fast examination exposed a loose fan blade-- simple to fix, yet left ignored, it could have shattered the motor. Moments like these underscore the worth of regular checks.

Quick List for Seasonal Prep

| Action | Frequency | Why It Matters |

|---|---|---|

| Filter cleaning/replacement | Every one month | Maintains airflow and performance |

| Coil and fin examination | Two times a year | Prevents air flow limitations |

| Refrigerant level check | Annually | Guarantees correct cooling capacity |

| Drain line clearing | Every 6 months | Avoids water damage and mold |

| Electrical system assessment | Yearly | Prevents abrupt shutdowns |

Pro Pointer: Beyond the Essentials

Did you know that gently lubing the fan motor bearings yearly can extend their life-span? It's a detail frequently overlooked however crucial. Also, shading your outdoor unit from direct sunlight can lower the compressor's workload, discreetly enhancing longevity. Keep in mind, the health of your air conditioning system is a reflection of the attention you offer it before it screams for help.

Jaleel White Then & Now!

Jaleel White Then & Now! Amanda Bynes Then & Now!

Amanda Bynes Then & Now! Mason Gamble Then & Now!

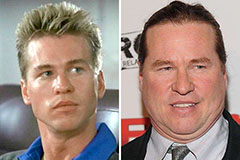

Mason Gamble Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now!